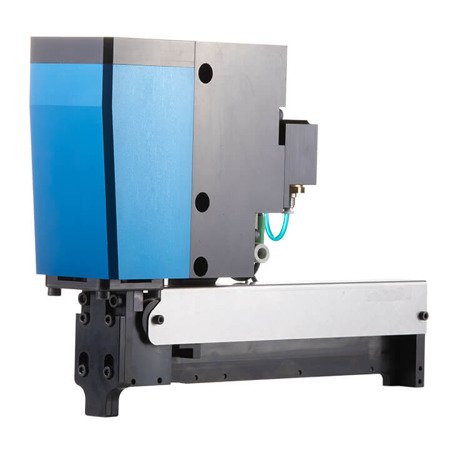

JK A-Fast A3L653 automation fastening system is built for 24/7 operations with a flawless uptime. The long magazine capacity model L is excellent for production lines where a lot of material needs to be processed. The unit has a high firing rate up to 500 rounds per minute. Moreover, the unit has a magazine sensor for full control over loading status and a feeding controller for full control of staple consumption. It´s durable with top of the line quality components engineered together for perfect performance and use a single connector for all functions. Making the system easy to integrate and operate in any production line. It is available in both pneumatic and electric actuation.

Technical Data

- Weight 8.2 kg ( 8.2 lbs )

- Dimensions 568 × 85 × 275 mm ( 21.4 x 1.9 x 6.9 in )

JK A-Fast A3L783 automation fastening system is built for 24/7 operations with a flawless uptime. The long magazine capacity model L is excellent for production lines where a lot of material needs to be processed. The unit has a high firing rate up to 500 rounds per minute. Moreover, the unit has a magazine sensor for full control over loading status and a feeding controller for full control of staple consumption. It´s durable with top of the line quality components engineered together for perfect performance and use a single connector for all functions. Making the system easy to integrate and operate in any production line. It is available in both pneumatic and electric actuation.

Technical Data

- Weight 8.1 kg ( 8.2 lbs )

- Dimensions 568 × 85 × 275 mm ( 21.4 x 1.9 x 6.9 in )

- Magazine capacity 207 fasteners

- Staple leg length 25 - 51 mm ( 1/4 - 7/8 in )

- Max. pressure 7 bar ( 102 psi )

- Speed (actuation time) 50 ms

- Power supply 24V DC, sensor type PNP

- Working pressure 5 - 6 bar ( 70 - 90 psi )

- Nose length 21 mm ( 0.8 in )

Features Automated Fastening System

Electric connector

Our units use a single electric connector for all functions. The connector makes it easy to install and perform effortlessly for maintenance or service disassembly.

Electric or pneumatic

Our automated fastening systems are available in both electric and pneumatic actuation, so they can easily be integrated to your production.

Magazine sensor

The magazine sensor controls the staple loading status. The sensor warns you when the magazine reaches low levels. Furthermore, it allows you to refill the magazine without interrupting production flow.

Feeding controller

Poka-yoke: This function warns when your automated fastening system is not firing any fasteners. It gives you full control of your staple consumption.

Continuous reloading cylinder

Our precision engineered continuous reloading cylinder makes it possible for autonomous staple firing at high speed. The reloading cylinder ensures that reloading fasteners are produced efficiently from the magazine. Only for A1H models.

Split free nozzle (A3)

Avoiding splits and cracks when fastening wood on wood is a must in manufacturing. Josef kihlberg’s patented split free nozzle solution prevents splits in material when fastening.

- Magazine capacity 225 fasteners

- Staple leg length 25 - 50 mm ( 1/4 - 7/8 in )

- Max. pressure 7 bar ( 102 psi )

- Speed (actuation time) 50 ms

- Power supply 24V DC, sensor type PNP

- Working pressure 5 - 6 bar ( 70 - 90 psi )

- Nose length 21 mm ( 0.8 in )

Features Automated Fastening System

Electric connector

Our units use a single electric connector for all functions. The connector makes it easy to install and perform effortlessly for maintenance or service disassembly.

Electric or pneumatic

Our automated fastening systems are available in both electric and pneumatic actuation, so they can easily be integrated to your production.

Magazine sensor

The magazine sensor controls the staple loading status. The sensor warns you when the magazine reaches low levels. Furthermore, it allows you to refill the magazine without interrupting production flow.

Feeding controller

Poka-yoke: This function warns when your automated fastening system is not firing any fasteners. It gives you full control of your staple consumption.

Continuous reloading cylinder

Our precision engineered continuous reloading cylinder makes it possible for autonomous staple firing at high speed. The reloading cylinder ensures that reloading fasteners are produced efficiently from the magazine. Only for A1H models.

Split free nozzle (A3)

Avoiding splits and cracks when fastening wood on wood is a must in manufacturing. Josef kihlberg’s patented split free nozzle solution prevents splits in material when fastening.